Profile

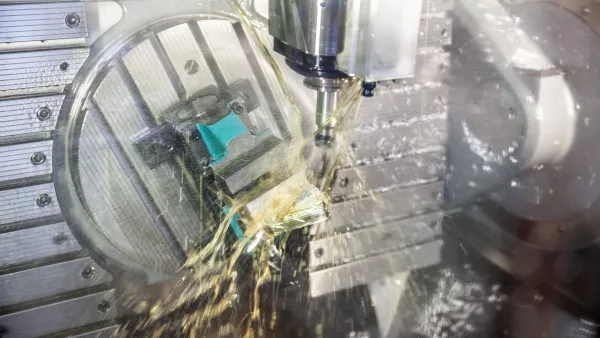

One of the most important manufacturing processes for the production of tools and products is machining with a geometrically defined cutting edge. In the Machining Technology laboratory, the basic process interrelationships are taught using the machining processes of drilling, turning and milling. To this end, the effects of the system variables (machine tool, tool, cutting material, workpiece material) and the manipulated variables (cutting speed, feed rate, depth of cut) on the process variables (power, force, heat, temperature) and the effective variables (tool wear, chip shape, workpiece surface and geometry) are studied. In the laboratory, students can acquire and deepen basic knowledge in the field of cutting technology through practical experiments.

Equipment

The machining experiments can be carried out with the following machine tools:

- 5-axis machining center with automatic tool change for machining complex workpieces, such as tools for sheet metal working, injection molds, impellers for turbines, pumps and compressors.

- Production lathe with main and counter spindles and 3 turrets, each turret having 12 driven tool stations. This allows milling operations such as grooves on the workpiece in addition to the usual turning contours.

- NC milling machine with three axes and without automatic tool change. The console milling machine is used for simple milling and drilling operations.

- Conventional pillar drilling machine with stepless adjustment of speeds and feeds.

- Tool setting device for measuring the tools used in the NC machines (machining center, production lathe, milling machine).

Contact & People

General contact details

| Phone | |

|---|---|

| Room | D 032 |

| On campus |

Building D

Leibnizstr. 9

88250 Weingarten |

| Postal address |

RWU Hochschule Ravensburg-Weingarten University of Applied Sciences Machining Technology P.O. Box 30 22

88216 Weingarten Germany |

Laboratory Manager