Profile

From ther roller dynamometer for the complete vehicle to microcontroller boards, the automotive engineering laboratory offers a wide range of modern technology that makes the theoretical content of your study program "tangible" through practical learning units.

Using a modern powertrain concept as an example, you can already see the need for the knowledge you have acquired during your basic study. You need knowledge of electrics, electronics and mechanics to design the drive, you need IT tools to evaluate measurement data and adjust systems, you need measurement and control technology to integrate and adapt mechatronic systems, you need materials science, mechanics and construction to design components solid and safely and, last but not least, you need mathematics, the language that makes the answers of physics understandable to you. Our aim is to lay these fundamentals and create cross-connections from them.

The laboratory infrastructure is also available for projects related to automotive engineering, such as Formula Student, student projects and final degree theses.

Contact roller dynamometer: Laboratory foreman Thomas Frei ( frei@rwu.de )

Laboratory Equipments and core teaching topics

Powertrain

Modern MAHA MSR 500/4 all-wheel drive roller dynamometer for single-axle/all-wheel drive vehicles with up to 520 kW/1040 kW wheel power and a top speed of 300 km/h

Cooling air flow with 33000 m³ air flow per hour

Determination of the engine power

Determination of tractive force curves

Carrying out realistic driving simulations taking into account driving resistances

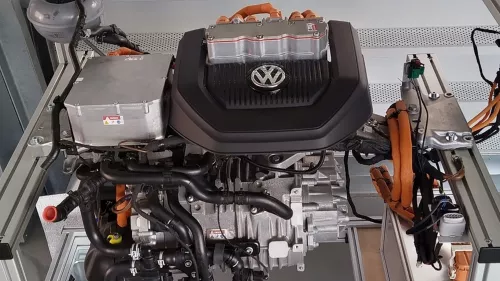

Electrified Powertrain

Electrical power determination using ZIMMER LMG 671

Mechanical power determination using the roller dynamometer

Determination of power losses

Determination of electrical and mechanical efficiencies

Calculation of driving resistances

Conclusion on driving performance and efficiency

High-voltage training setup

High-voltage system structure of the VW E-Golf/e-up! mounted in a freely accessible location

Qualification of the participants according to level 1E (FuP) DGUV I 209-093

Analysing the electrical power flow from the battery to the electric motor

Insight into the professional and safety-related work processes of a Skilled Electrical Peron

Vehicle aerodynamics

Inflow of a vehicle model in the wind tunnel

Consideration of the flow conditions around the vehicle model

Analysis of the forces acting on a vehicle in an airflow

Determination of aerodynamic parameters

Design criteria of modern vehicles

Brake technology

Design and function of modern car brake systems

Consideration of the chain of effects from the pedal force to the wheel braking force on the vehicle and on the component structure

Determination and calculation of design-relevant variables

Carrying out a brake efficiency test in accordance with § 29 StVZO using an HU adapter on the brake test bench

Chassis technology

Continuous measurement of toe and camber of the FA over the total wheel travel

Investigation of the whee travel kinematics

Exemplary determination of the wheel travel curve based on the logged measured values

Conclusion on driving behavior and design criteria of mass-produced vehicles

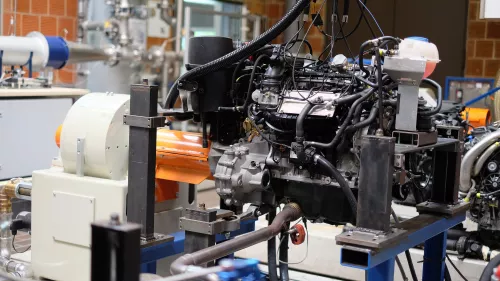

Engine test benches

ECU calibration using the INCA (ETAS) calibration, measurement and diagnostics software tool

Engine application using an in- cylinder pressure measuring chain from AVL

Analysis of the combustion process based on the internal cylinder pressure curves

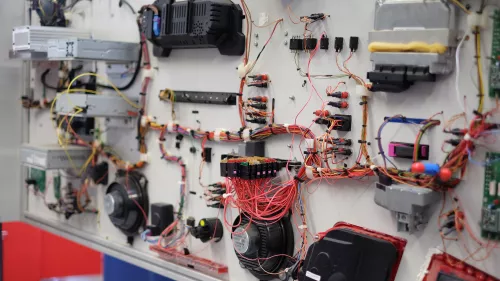

Electrical- and bus systems

Electrics, from the power generation to management systems

Basics of digital bus systems

Analysis of bus communication on the physical level

Test and analysis of data traffic using the CANoe developer tool from VECTOR

Configuration and implementation of a residual bus simulation

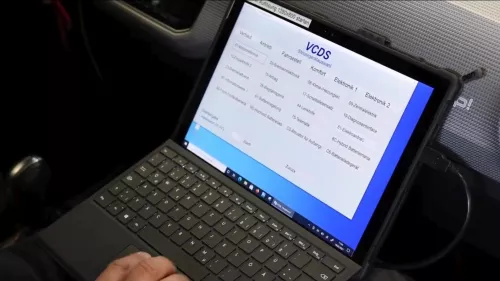

Vehicle diagnostics

OBD diagnostics using AVL and VCDS diagnostic software

Dispaly of project-related parameters

Display and analysis of vehicle data

Carrying out actuator tests

Microcontroller programming

Microcontroller basics (structure, functions, pinout)

Programming exercise examples

Designing an own circuit board using a graphical layout editor

Assembly and programming of the self-made circuit board

Contact & People

General contact details

| Phone | |

|---|---|

| Room | H 057 |

| On campus |

Building H (main building)

Doggenriedstrasse 70

88250 Weingarten |

| Postal address |

RWU Hochschule Ravensburg-Weingarten University of Applied Sciences Automotive engineering and mechatronics P.O. Box 30 22

88216 Weingarten Germany |

Laboratory manager

Laboratory team

- Building H (main building)

- Room H 057